Final report on Alaska Airlines Flight 1282 in-flight exit door plug separation

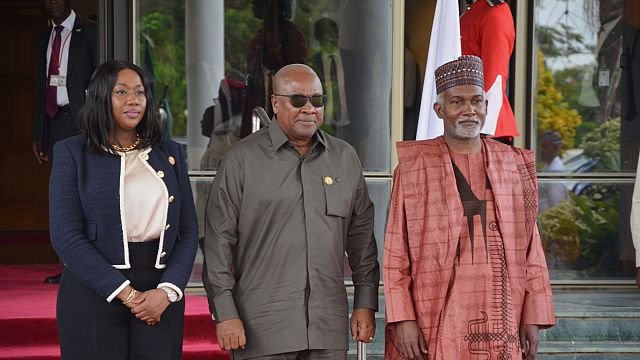

NTSB investigators examine the door plug from Alaska Airlines flight 1282, a Boeing 737-9 MAX.

In-Flight Separation of Left Mid Exit Door Plug, Alaska Airlines Flight 1282, Boeing 737-9, N704AL

What Happened

On January 5, 2024, a Boeing 737-9 airplane operated by Alaska Airlines as flight 1282 experienced an in-flight separation of the left mid exit door (MED) plug and rapid depressurization when climbing through about 14,830 ft after takeoff from Portland International Airport (PDX), Portland, Oregon. One flight attendant and 7 passengers received minor injuries; the captain, the first officer, 3 flight attendants, and 164 passengers were uninjured; and the airplane sustained substantial damage. The flight and cabin crews executed the emergency procedures in response to the rapid depressurization, and the flight returned to PDX for a safe landing.

The airplane had a hole in the fuselage where the left MED plug (a rectangular airframe structure about 29 inches wide and 59 inches high) had been installed. Components on the fuselage frame that surrounded the hole, including fittings and assemblies associated with the left MED plug installation, were damaged. The passenger seats and cabin interior located nearest the hole were also damaged, and a seatback tray table, two seat headrests, and cabin interior panels were missing. The airplane’s left MED plug and some of the seat and interior pieces were located on the ground (along the airplane’s flight path) and recovered. Multiple components associated with the left MED plug installation, including four bolts that would secure the left MED plug from moving upward vertically, were not located.

View on scene photos on

NTSB Flickr

What We Found

We determined that the probable cause of this accident was the in-flight separation of the left MED plug due to Boeing’s failure to provide adequate training, guidance, and oversight necessary to ensure that manufacturing personnel could consistently and correctly comply with its parts removal process, which was intended to document and ensure that the securing bolts and hardware that were removed to facilitate rework during the manufacturing process were properly reinstalled. Contributing to the accident was the FAA’s ineffective compliance enforcement surveillance and audit planning activities, which failed to adequately identify and ensure that Boeing addressed the repetitive and systemic nonconformance issues associated with its parts removal process.

What We Recommended

As a result of this investigation, the National Transportation Safety Board makes the following new safety recommendations.

To the Federal Aviation Administration:

- Once you complete the certification of Boeing Commercial Airplanes’ design enhancement for ensuring the complete closure of Boeing 737 mid exit door (MED) plugs following opening or removal, issue an airworthiness directive to require that all in-service MED plug-equipped airplanes be retrofitted with the design enhancement. (A-25-15)

- Revise your compliance enforcement surveillance system to ensure that it provides the necessary functionality for Federal Aviation Administration managers and inspectors overseeing production approval holders to effectively identify, record, track, and resolve recurring and systemic discrepancies and nonconformance issues, including those related to specific manufacturing processes. (A-25-16)

- Revise your audit planning activities to ensure that they provide the necessary functionality for Federal Aviation Administration managers and inspectors overseeing production approval holders to effectively identify, record, track, and resolve recurring and systemic discrepancies and nonconformance issues, including those related to specific manufacturing processes. (A-25-17)

- Revise your records systems to ensure that they provide the necessary records for Federal Aviation Administration managers and inspectors overseeing production approval holders to effectively identify, record, track, and resolve recurring and systemic discrepancies and nonconformance issues, including those related to specific manufacturing processes. (A-25-18)

- Once the actions in Safety Recommendations A-25-16 through -18 are completed, dDevelop guidance for Federal Aviation Administration managers and inspectors who provide oversight of production approval holders on how to identify, record, track, and effectively address repetitive and systemic discrepancies and nonconformance issues, to include strategies for assessing the effectiveness of corrective actions taken by the production approval holder during the previous year when developing next year’s certificate management plan. (A-25-19)As a result of this investigation, the National Transportation Safety Board will make the new safety recommendations to the Federal Aviation Administration and the Boeing Company.

Provide Federal Aviation Administration managers and inspectors who provide oversight of production approval holders with recurrent training on how to identify, record, track, and effectively address repetitive and systemic discrepancies and nonconformance issues, to include strategies for assessing the effectiveness of corrective actions taken by the production approval holder during the previous year when developing the next year’s certificate management plan. (A-25-20)- Retain historical compliance enforcement surveillance and audit records older than 5 years and provide Federal Aviation Administration managers and inspectors access to these records to enhance their oversight planning for production approval holders. (A-25-21)

- Convene an independent panel to conduct a comprehensive review of Boeing Commercial Airplanes’ safety culture. The findings should be used to enhance the ongoing development of Boeing’s regulatory safety management system (SMS) and the integration of its SMS into its broader quality management system. (A-25-22)

- Notify operators of the circumstances of the accident involving Alaska Airlines flight 1282, and encourage them to review their flight crew training programs and ensure that they include hands-on, aircraft-specific training and procedures for each type of oxygen system in the operators’ fleet, to include establishing and maintaining communications when the oxygen masks are donned and removed while participating in realistic emergency procedures training scenarios. (A-25-23)

- Review and revise, as necessary, the design standards that apply to portable oxygen bottle design to ensure that they adequately address ease of use and quick donning in an emergency situation, including considerations for the effort needed to remove the mask from its packaging. (A-25-24)

- Require operators of airplanes equipped with a cockpit voice recorder (CVR) to incorporate guidance into company standard operating procedures, emergency protocols, and postincident and postaccident checklists—applicable to both flight crew and non-flight crew personnel—detailing actions to preserve CVR recordings as soon as practical after completion of a flight with a reportable event. (A-25-25)

To The Boeing Company:

- Continue the certification process for the design enhancement for mid exit door plugs to ensure that, once the design enhancement is certified, all applicable newly manufactured airplanes are equipped with the enhancement. (A-25-26)

- Once the design enhancement for mid exit door (MED) plugs is certified, issue a service bulletin to address retrofitting in-service MED plug-equipped airplanes with the design enhancement. (A-25-27)

- Apply your updated safety risk management process to current and future revisions to Business Process Instruction “Perform Part or Assembly Removal” to ensure that it provides clear and concise guidance for determining when a removal record is needed. (A-25-28)

- Develop recurrent training on Business Process Instruction “Perform Part or Assembly Removal” for Boeing manufacturing personnel that emphasizes the importance of removal records for product safety, prepares personnel to consistently and correctly determine when a removal record is needed, and ensures that a removal record is generated when required. (A-25-29)

- Develop a structured on-the-job training program that identifies and defines tasks necessary for manufacturing personnel to be considered fully qualified in their job series and includes a grading system for trainers and trainees to track progress and determine competence.(A-25-30)

- Document and archive the results of training provided and received as part of the program recommended in Safety Recommendation A-25-30 to support future data analysis. (A-25-31)

- Revise your safety risk management process to ensure that it 1) identifies the root causes of manufacturing process compliance issues, like the persistent deficiencies with Business Process Instruction “Perform Part or Assembly Removal” and other production process inconsistencies identified in this investigation, and 2) evaluates the effectiveness of corrective actions. (A-25-32)

- As you integrate your quality management system and safety management system, develop a process that can identify escapes that result from human error, assess them using a system specifically designed to identify factors that contribute to such errors, and implement effective mitigation strategies. (A-25-33)

We also reiterated the following safety recommendations.

To the Federal Aviation Administration:

- Require all newly manufactured airplanes that must have a cockpit voice recorder (CVR) be fitted with a CVR capable of recording the last 25 hours of audio. (A-18-30)

- Require retrofit of all cockpit voice recorders (CVR) on all airplanes required to carry both a CVR and a flight data recorder with a CVR capable of recording the last 25 hours of audio. (A-24-9)

- Conduct a study to determine the factors that affect caregivers’ decisions about the use of child restraint systems (CRSs) when traveling on a Title 14 Code of Federal Regulations Part 121 air carrier airplane with children under the age of 2 and to understand the challenges associated with using CRSs; publish the study findings. (A-21-40)

- After the action in Safety Recommendation A-21-40 is completed, use the study findings to direct the Federal Aviation Administration’s efforts to increase child restraint system usage. (A-21-41)

- Coordinate with your member airlines to develop and implement a program to increase child restraint system (CRS) usage in airplanes; this effort should include collecting data to determine the program’s effectiveness at increasing CRS usage. (A-21-45)

Video

Board Meeting on June 24, 2025

https://www.youtube.com/watch?v=qkixkD96ATENTSB Investigative Hearing - Alaska Airlines flight 1282 (Day 2)

https://youtu.be/EZuO2dtGVXoWatch: NTSB Investigative Hearing - Alaska Airlines flight 1282 (Day 1)

https://youtu.be/a8zqkXSL3HwNTSB B-Roll - Alaska Airlines Flight 1282 Boeing 737-9 MAX

https://www.youtube.com/watch?v=QoiGuuGZPNcWhat's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0